Dalian caseberg equipment manufacturing co. LTD

Marketing center: dalian Shahekou District changxing street 137-139 fuhung international tower B 2301

Mail box: info@dlcosbog.com

Negotiation hotline: +86-0411-62278511

Contact number: +86-18018919688

Company website: WWW dlcosbog.com

Kesberg fluid technology (qingdao) co.LTD

Marketing center:137 Yanqing Road, Huanxiu office, Jimo District, Qingdao

The higher service temperature of commonly used aluminum and aluminum alloy tube shall not exceed 200℃; For pressure piping, the service temperature shall not exceed 160℃. More aluminum and aluminum alloy pipes are used in cryogenic engineering. Installation of aluminum and aluminum alloy pipes, transportation and storage of aluminum and aluminum alloy pipes should be taken care to avoid collision, extrusion and abrasion of the pipes. When stored, the pipes should be separated from iron, stainless steel, copper and other metals to avoid electrochemical corrosion.

Aluminum and aluminum alloy pipe cutting can be used by hand saw blade, machinery (sawing machine, lathe, etc.) and grinder, not flame cutting; Groove should be used for mechanical processing, do not use oxygen - acetylene flame. Aluminum and aluminum alloy pipe connections are generally welded and flanged. Manual argon tungsten arc welding, oxyacetylene welding and semi-automatic argon welding of melting pole can be used for welding. When pipe insulation, asbestos rope, asbestos board, glass wool and other materials with alkaline, should choose neutral insulation materials.

Due to the low strength of aluminum alloy at high temperature, the welding seam is easy to collapse or burn through. The backing plate has a circular arc groove towards the weld to ensure the back of the weld is well formed. Using ER5356 welding wire, manual TIG welding and semi-automatic MIG welding of 5A06 and 6061 aluminum alloy have obtained good welding joints. Because semi-automatic MIG welding is a droplet transition process, it is not as stable as TIG welding. There is a small amount of porosity in the weld metal of MIG welding.

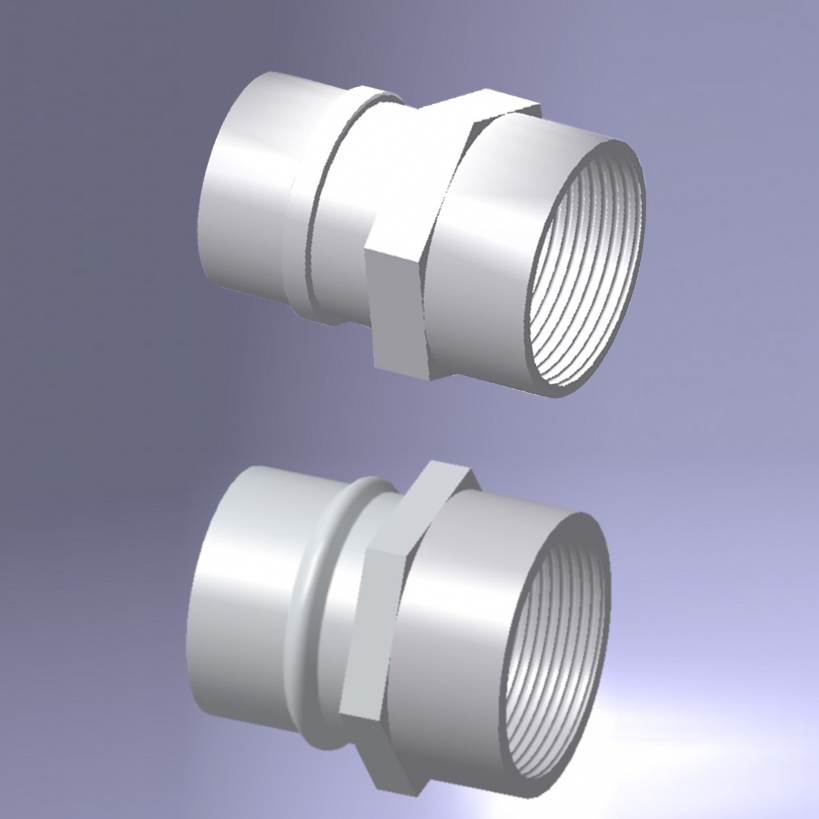

The inner surface of galvanized steel tube is bright and clean. Small pressure loss of compressed air, energy saving. Galvanized steel pipe is beautiful and simple. Aluminum alloy is easy to install and quick to plug. Installation costs are low. Aluminum alloy is easy to disassemble, move and modify. The price of aluminum alloy pipe and joint is higher than that of galvanized pipe. Aluminum alloy steel tube can not be used as a water pipe, because the aluminum tube is less rigid than galvanized pipe, but very flexible.