Dalian caseberg equipment manufacturing co. LTD

Marketing center: dalian Shahekou District changxing street 137-139 fuhung international tower B 2301

Mail box: info@dlcosbog.com

Negotiation hotline: +86-0411-62278511

Contact number: +86-18018919688

Company website: WWW dlcosbog.com

Kesberg fluid technology (qingdao) co.LTD

Marketing center:137 Yanqing Road, Huanxiu office, Jimo District, Qingdao

When aircraft fuel system USES aluminum alloy pipe connector to transfer oil, it has to bear the varying oil pressure. In the hydraulic pulse test simulating the actual working condition, the pipe connector fails because the pipe near the assembly position has cracks through the inner and outer surface.

By scanning electron microscope observation, the crack originated from the fringe micro-defects on the outer surface of the catheter. Under the action of the hydraulic pulse, the crack continuously extended ductility along the pipe diameter to the inner surface of the catheter. When the crack area of the catheter could not withstand the peak pressure of the hydraulic pulse, the crack directly penetrated into the inner surface of the catheter. The measures to improve the resistance to hydraulic impulse fatigue of the pipe connecting parts are put forward.

In order to realize the automatic welding of the loop seam of aluminum alloy pipe, according to the characteristics of the loop seam of aluminum alloy pipe, the test equipment for the loop seam automatic welding was developed. A series of tests were carried out to determine a set of automatic welding process specifications for aluminum alloy pipe loop seam.

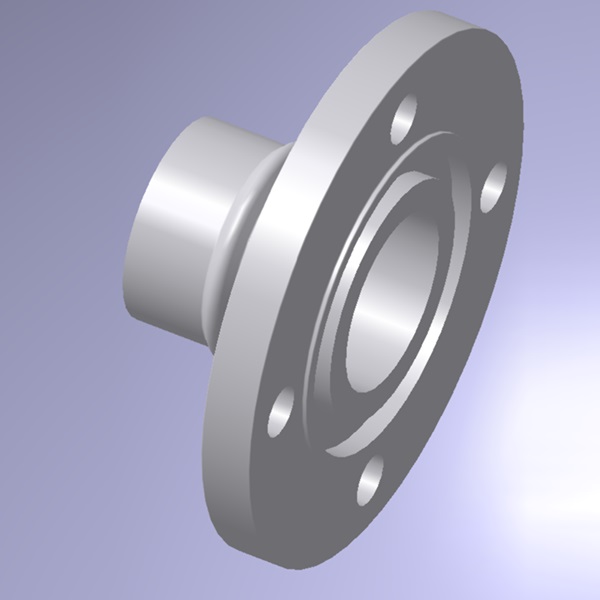

Oblique core-pulling is one of the difficult points in die casting design for castings with oblique hole or concave and convex. The shape of pipeline casting is complex and belongs to irregular thin-walled porous casting. In addition to the core pulling in the direction of mold opening and both sides of the core pulling in the direction of moving and fixed mold, the casting inner wall also has an oblique hole, which requires the core pulling in an oblique direction.

The practical structure of die casting die for dalian aluminum alloy pipe parts is discussed. The mould adopts the two-stage joint core-pulling mechanism of hook, tooth fan and rack, and realizes the inclined core-pulling of pipe casting by using the die opening force, and at the same time realizes the other two side core-pulling of pipe casting through the corresponding two sets of inclined pin and slide block mechanisms. The mould structure is compact, the work is reliable, the molding casting quality is good.